Diseño MUY interior

Vinçon

12/06/13. (Sala 297)

La Sala Vinçon presents “Real Interior Design”, where a selection of objects with the most refined design are displayed, objects which are probably until this point quite unfamiliar, even to many of its owners.

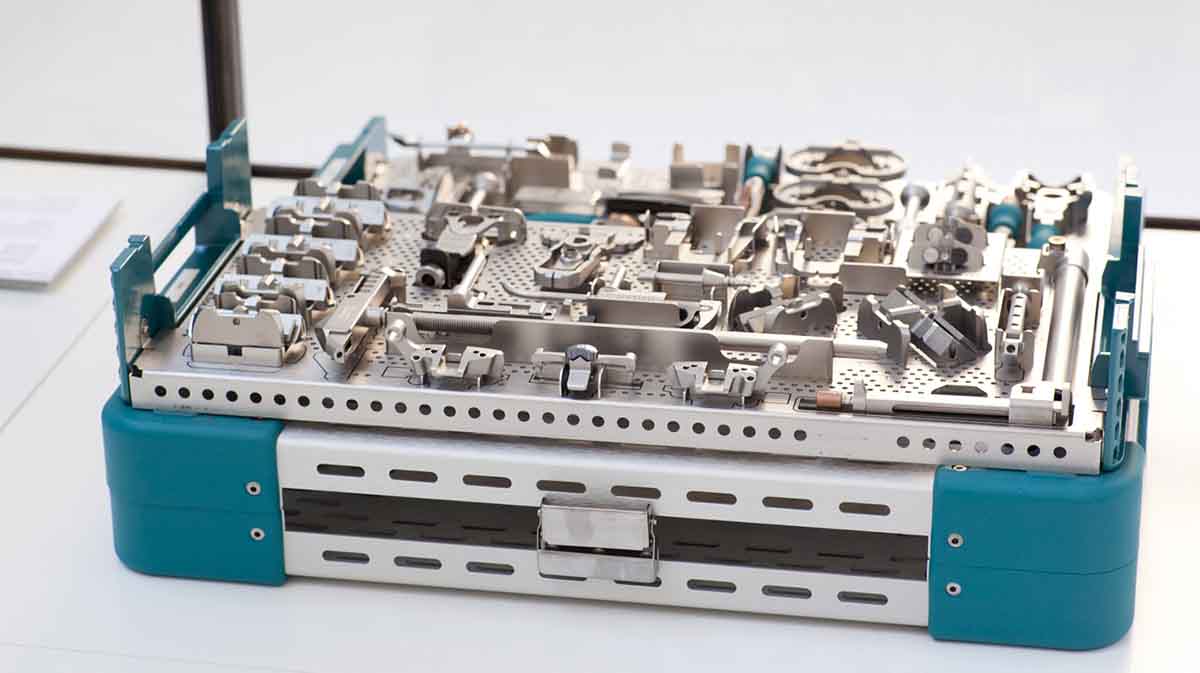

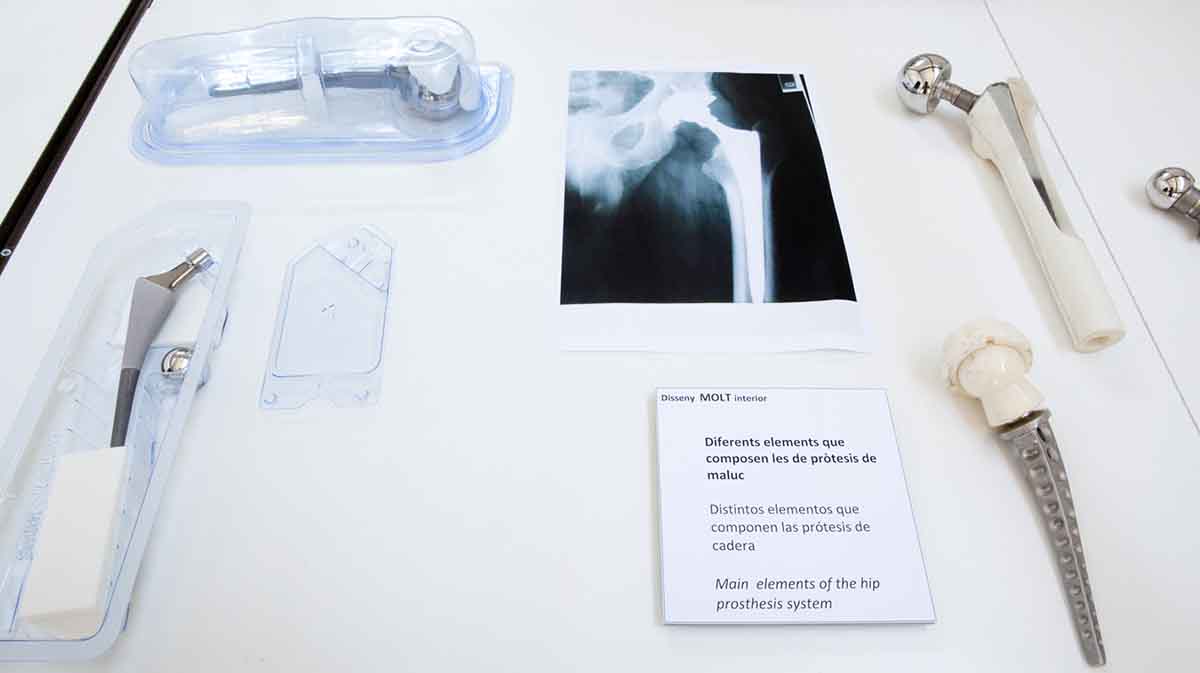

Playing on the double meaning of interior design the exhibition includes a collection of hip and knee prostheses used in current surgery, as well as the necessary instruments to carry out the implantation.

The 1992 Milano Trienniale held an exhibition that displayed, for the first time, some prostheses under the name of “replacement parts”. Since this exhibition we have tried to learn more about this industry, which has evolved so much but which is not sufficiently visible by a public that is not close to the medical sector.

With the help of Dr. Felix Escalas we were finally able to see many of these parts which may well confuse a novice with sculptures or jewelry.

Discovering all that HR the distributor for the American brand Striker had prepared for our visit confirmed what we already sensed: We were facing a pure design project, a level that would embarrass many famous manufacturers and designers we admire.

But this was just the first act.

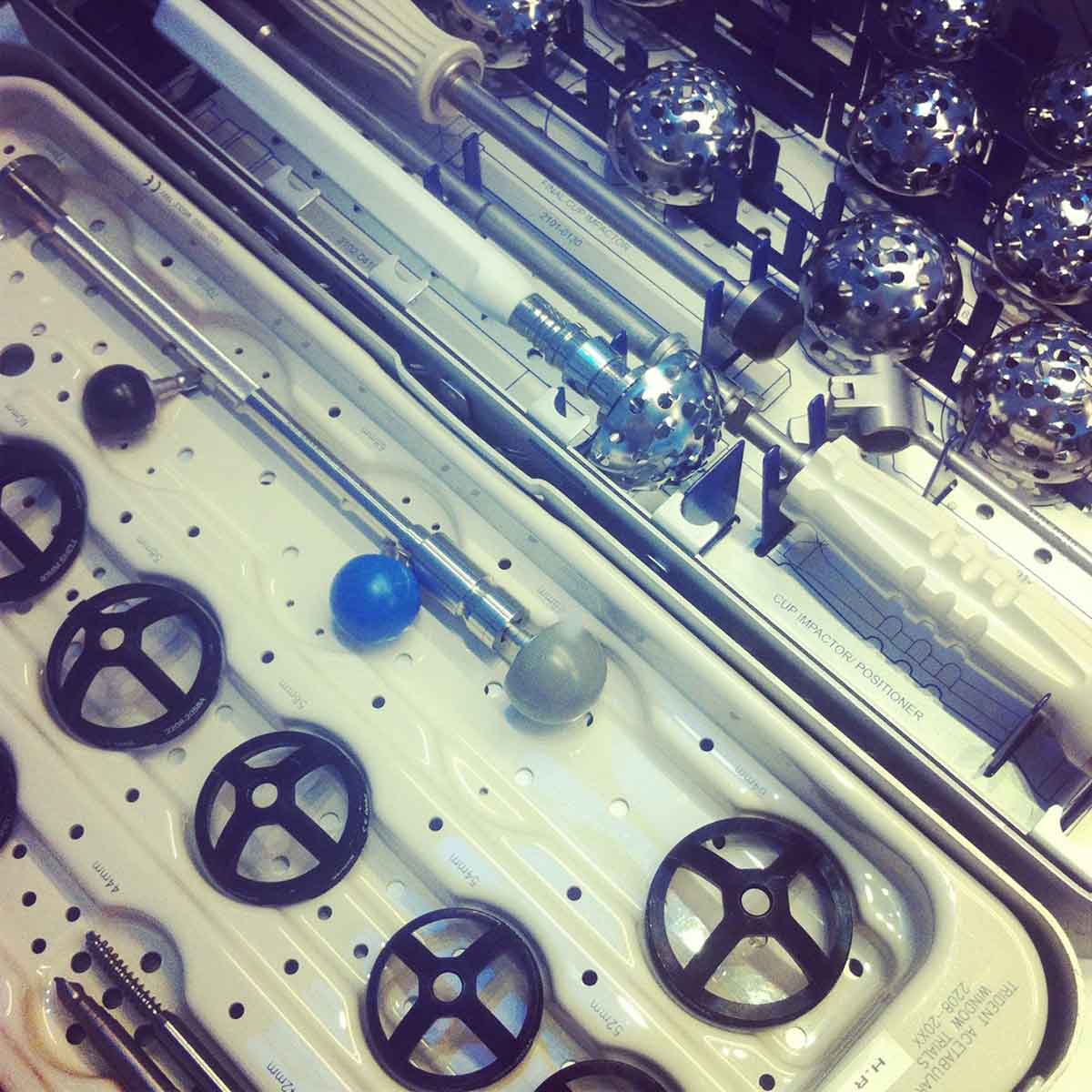

The second surprise was when we asked a naive question to both Dr. Escalas and the distributors about those little wonders: We wanted to know how the surgeon changed an old knee for a new one.

The answer was obvious: with tools.

Luckily we wanted to see the tools. Luckily we also get to show them at La Sala Vinçon.

Ultimately, it is an example of design that no one would want to criticize its excellence.

We would like to add that those who are apprehensive can see everything which is on display at the exhibition lightheartedly.

The surgeon’s opinion

The design of an implant or joint prosthesis was initially developed by trial and error methods. The idea that it was essential to accurately reproduce the anatomical structure of the joint was eventually replaced by scientific design.

Today, before implementing a change in the design of a prosthetic hip or knee joint it is compared with existing results and this minimizes the risks patients face when exposed to incorrect innovation.

The development of a new idea entails a necessary sequence of monitoring and search steps. This tests the mechanical and biological viability. We mustn’t forget that human beings are being treated. Once innovation is tested and verified, the next step is the manufacturing process, commercialization and clinical use.

The initial mechanical test includes:

– The selection of suitable materials, resistance, friction, etc.

– The ideal selection of the bone fixation system. Biological fixation, cement, etc.

– The anatomical-geometric analysis for fitting the bone, geometric characteristics and the architecture of the implant.

– Testing of the mechanical interaction of the bone with the implant by computer simulation.

– Testing of the accumulative wear and fatigue over time. The biological viability tests include the biological response to the compatibility of the materials used and the particles derived from the wear of the bone and implant which will determine the longevity of the implant.

The last phase of the design includes the necessary instruments to put the prosthesis, precision tools for the preparation of the patient’s bone through minimal surgical invasion and the simplest possible handling for the surgeon.

The described process is multidisciplinary as it involves the surgeon, engineer and biologist.

In short, it is the surgeon’s responsibility to correctly select the implant for each patient and specific pathology. The patient is the most important factor and this selection is the surest guarantee to success or failure in an operation.

Dr. Felix Escalas Llimona

Orthopaedic Surgery and Traumatology

Until 20 July 2013.